Introduction

Thank you for your interest in our company. Signal-Print Ltd. was founded in 1998 based on our printing experience of the previous years. As a result of the efforts to fulfill our customers’ demand in reliable and flexible way with high quality products we have become a dynamically developing medium-sized company during the years. Focusing on the demands of the market we have invested our profit in buying new equipment of modern technology to raise not only the capacity and environmental awareness but also continuously improve the quality level and working conditions. As one of the stages of this process – in addition to the assembly sector – we set up our pulp plant in 2020.

PAPER PULP

PACKAGING PLANT

ISO 9001 · ISO 14001

Aligning with demands, we have expanded our activities with new production technology, modern production equipment at a 2.000 m2, working area for design and production of paper pulp packaging. Our products meet the highest quality standards accepted in this industry. We have ISO 9001 and ISO 14001 certifications for this area as well.

ENVIRONMENTAL

CONSCIOUSNESS

100% recyclable

100% compostable

About pulp

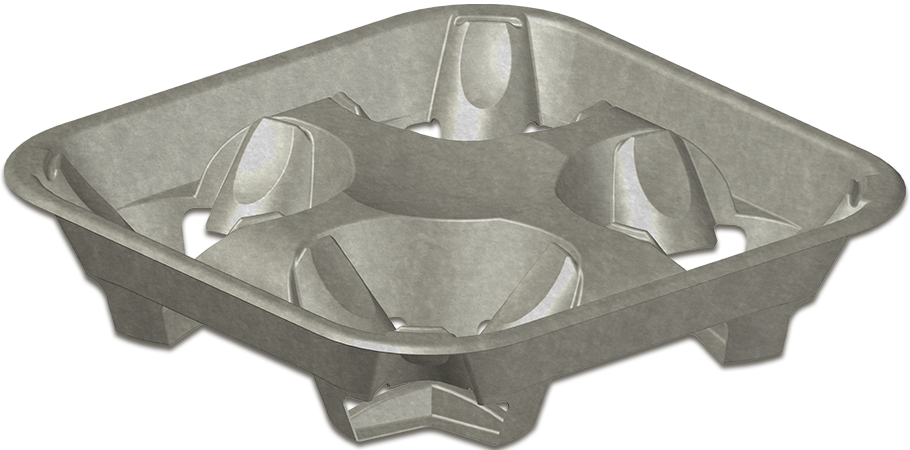

Packages of moulded fibre are made of water and recycled waste paper, which can be shaped as needed and again 100% recyclable. It minimizes impacts of human activities on environment by means of reducing NOx and COx emissions. It is a sustainable product, which is fully bio-degradable and compostable in compliance with ISO 14001 and with EU standards. It provides maximum protection for the products as it fills the external packaging, saves spaces, and it can be stacked easily. Moreover it is cost-effective and electrostatics neutral.

BST IP6000

Fully automatic production line

PROCESS

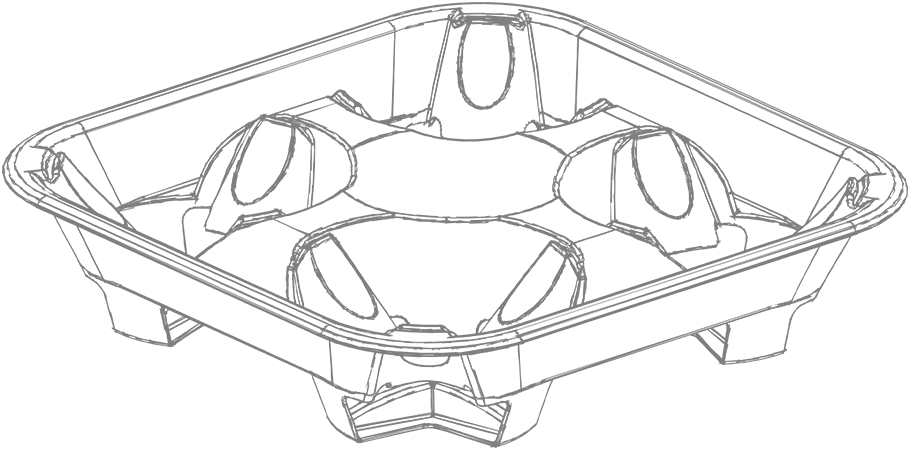

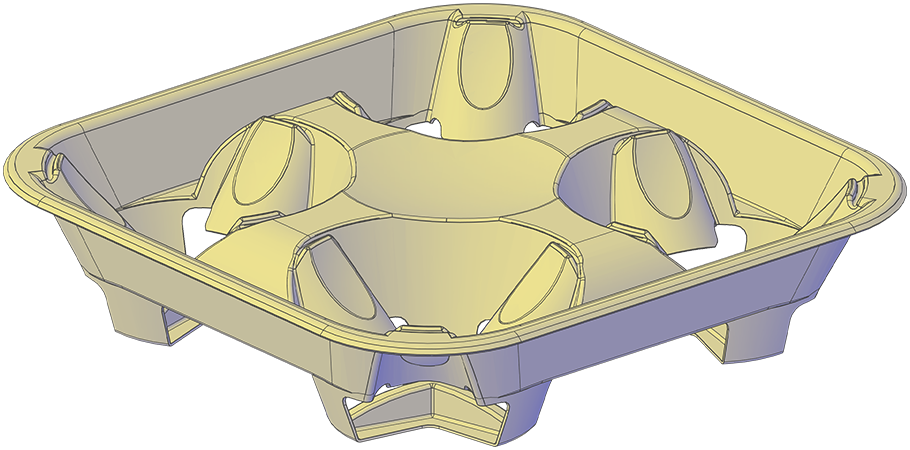

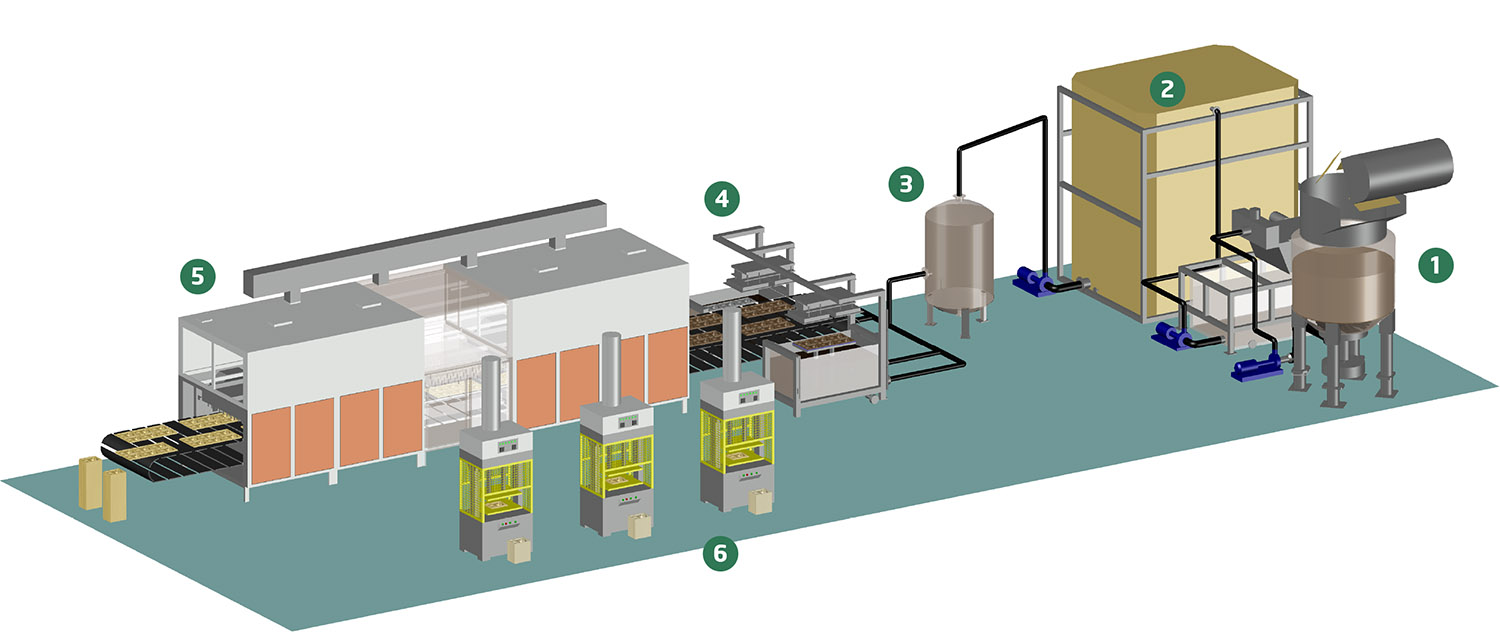

Before production we create a drawing based on our own design according to the requirements of the customers. Upon approval the design, there is created a prototype with test tool and on approving the prototype, the final production tool is created.

The production starts with moulding the pulp from recyclable waste paper and water (figure 1-3). After that the moulded pulp (4) is dried in a 17-meter-drying-conveyor (5). If it is required the products are after-pressed in a hot mould to achieve a smooth surface by high temperature and high-pressure. (6). Once the order is manufactured, it is checked by quality assurance and packed and it is made available from our factory to collect. Of course, we could take care of shipping as well.

Production line is suitable

for recycling of

2000 TONNES

OF WASTE PAPER YEARLY

Application

With the packages produced by this technology, the surface of the products can be fully traced. The moulded pulp packages prevent the movement within the packaging, and by creating different deformation zones, the transmission of vibrations can be significantly reduced inside the packages. Thanks to our developments the dusting can be significantly reduced, an extra protection can be provided with appropriate design. Such packages are even perfect for storing larger, more heavy items too. It is an ideal choice for fragile products, for mass production or luxury final products also. Pulp packages are free of hazardous substances, heavy metals, therefore disposable flowerpots can also be made of it, as they decompose after planting.

automotive · cosmetics

electronics · food industry

manufacturing industry

mechanical engineering

light industry · agriculture...

Contact

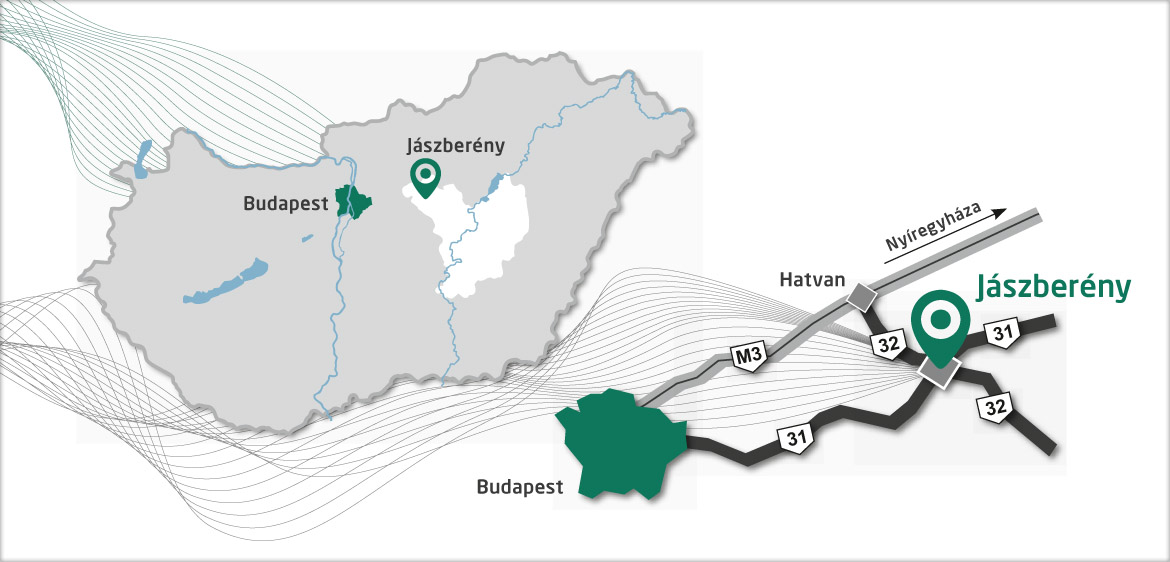

Signal-Print Printing and Trading Ltd.

Pulp plant: 5100 Jászberény, Október 23-a út 8.

Office: 5100 Jászberény, Jásztelki út 83.

Post address: 5100 Jászberény, Pf. 83

Phone: +36 57 500 970

Fax: +36 57 500 975

E-mail: signal@nyomdasz.hu

Web: www.nyomdasz.hu

Contact us!

Fields marked with * are required.